Customers sometimes ask us about using barcode labels or RFID tags to mark assets for fuel and lubricant deliveries.

- When should you use RFID over barcodes or vice versa?

- What is the cost difference?

- What kinds of companies are using RFID vs. barcodes?

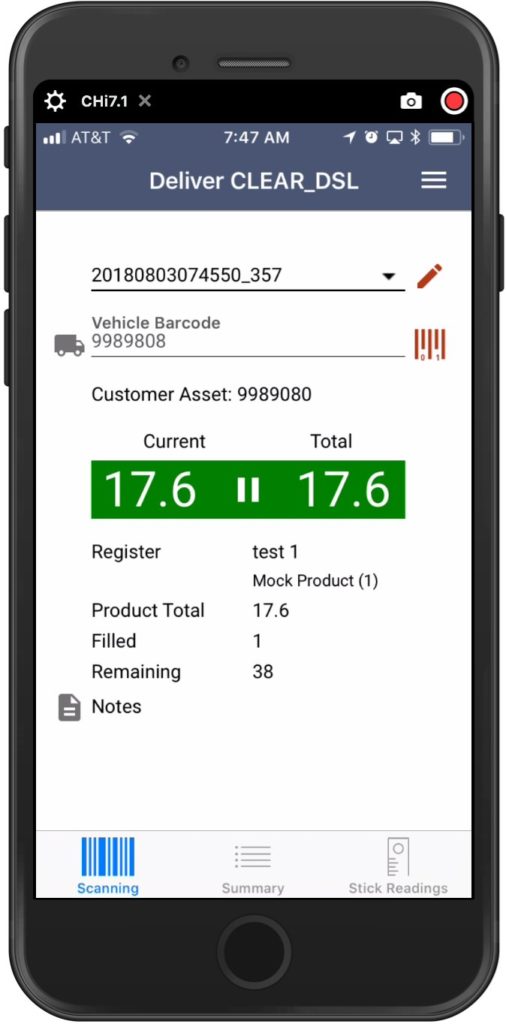

When you use fuel or lubricant delivery software, the driver usually scans a barcode or RFID tag to confirm that the vehicle or tank is being filled. This way, the driver doesn’t have to manually enter a value, write down a tank number, or risk recording the wrong ID. The mobile device can check if the product is compatible when the driver scans the label or tag. This ensures that the driver won’t accidentally put dyed diesel in a gas tank or mistakenly deliver 5W-20 conventional oil into a synthetic tank.

Understanding the Difference Between Barcodes & RFID Tags

Barcodes

- Labels come in two main types: 1D (like UPC codes) and 2D (such as QR codes or driver’s licenses)

- Printed on various materials like paper, polyester, polypropylene, or metal, which determines their durability

- Different adhesives are used to stick them to different materials

- The durability of barcode labels varies depending on their intended use

- 2D barcodes can hold up to 4,000 characters of data, making them capable of storing more information than 1D barcodes

RFID Tags

- Two main types of RFID tags: High Frequency (HF) and Ultra High Frequency (UFH)

- HF tags have a read range of around 8 inches where as UHF can range from 2-10 feet

- For using UFH tags on metal surfaces, a specifically designed metal-mount tag is necessary

- RFID tags, like barcodes, can have specialty adhesives

- While RFID can be read through materials like clothing, it does not perform well with liquids or metal (If a tag is placed on a poly tank filled with liquid, it will not read through the tank)

When should you use barcodes vs. RFID?

RFID Tank Delivery

RFID technology is commonly used for fuel and lubricant delivery, implementing HF tags known as buttons. To read these buttons, the tag scanner/reader needs to be placed in close proximity, usually within a few inches. The benefit of RFID buttons in dirty or harsh environments is that they can still be read even if they are covered in dirt or grime. On the other hand, if a 1D barcode label is damaged, it cannot be scanned. In most cases, a 2D barcode can sustain some damage and still be scanned.

One drawback of RFID tags is that they are raised, making them more susceptible to being washed off easily when power washing a truck or tank. Additionally, when dealing with multiple buttons, it can be challenging to find a specific one since they may lack a human-readable value visible to the driver. While some smartphones can read high frequency RFID tags, RFID readers tend to be more expensive compared to barcode scanners. A UHF-capable RFID mobile scanner typically costs between $3,000-$4,500. Overall, the options available for RFID devices are significantly limited compared to barcodes.

Barcode Tank Delivery

Both V imagers (such as phone cameras) and specialized barcode scanners have the ability to read barcodes. Barcodes come in extremely durable formats like polyester, polypropylene, and KIMDURA. Formats like this are designed specifically to withstand rugged outdoor conditions for several years. Based on our experience, there is no clear advantage of using RFID instead of barcodes when using fuel and lubricant delivery software or handling bulk products. Nowadays, barcode materials and adhesives are capable of meeting the durability requirements of most scenarios involving the distribution of bulk products. This eliminates the need for expensive RFID tags and reader hardware.

What’s the cost difference between RFID and barcodes?

Hardened high frequency RFID tags usually cost between $3 and $6 per tag. The exact price depends on the quantity purchased (for quantities below 1,000, it’s around $130 for 25 tags). On the other hand, ultra high frequency RFID tags are around $0.10 per tag. Metal mount UHF tags can cost over $1 per tag.

On the other hand, durable barcode labels are much more affordable. They start at around $0.01 per label. For instance, a set of 2,500 barcode labels would typically cost around $3,000.